In commercial display scenarios, interaction between people and screens has become a fundamental requirement. Taking products used in subway track areas, which typically have high humidity and contain a lot of particulate matter (mainly iron dust and dirt), as an example, traditional fine-pitch display products are susceptible to bumps or vibrations, leading to LED beads falling off or failing, which significantly impacts product lifespan and user experience.

For instance, to address this common issue, the Beijing Subway Line 17 has installed customized GOB commercial displays designed by Sansi LED along both sides of the platform walls at all 21 stations of the line. So, what is GOB? What are its practical application advantages in subway stations?

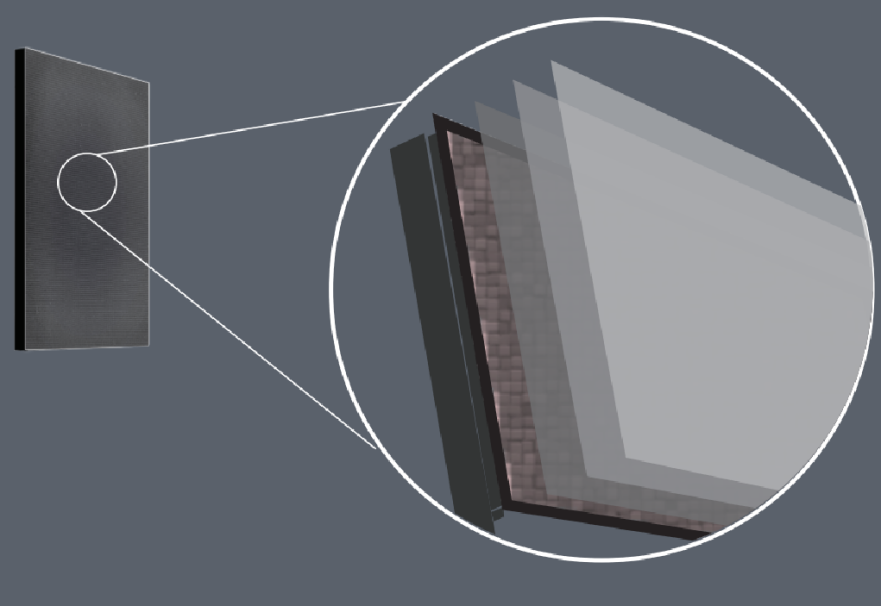

GOB (Glue On Board) is a module-level protective technology that involves applying a sealing process to the surface of the product module. This changes the originally granular pixel points on the light panel into a flat panel, transforming point light sources into surface light sources, resulting in a more uniform LED lighting effect and providing higher flatness to the product. The display effect, viewing angles, contrast, and other parameters are significantly enhanced. It is reported that GOB products can also reduce glare and relieve visual fatigue.

GOB Application in Harsh Environments: Stable Image Quality, High Definition Experience, Reliable Use

Taking the Beijing Subway Line 17 project as an example, the back of the LED display is not in direct contact with the installation wall, and the unit box uses a sealed box structure from the back. The front module utilizes GOB surface sealing treatment, which can prevent short-term water ingress from accidental back and front impacts.

Additionally, for the indoor track environments, which are prone to corrosion, humidity, and mist, GOB displays tackle common issues found in conventional non-sealed modules, such as water resistance, impact resistance, and the tendency for LED beads to fall off during contact. It effectively prevents the intrusion of dust pollution from the subway environment, avoiding problems where dust adheres to the LED beads, causing them to fail.

Overall, under harsh working conditions, GOB technology demonstrates excellent adaptability. (See the table below)

GOB Module | Non-encapsulated module | |

Waterproof and dustproof level | ≥IP65 true dust and waterproof | × |

Shock resistance | Great | Poor |

Oxidation resistance | Great | Poor |

Moisture resistance | It can prevent moisture in places with temperature difference and pressure | There is a potential risk of lamp failure after the lamp beads and PCB absorb moisture |

Installation/Transportation | It will not cause damage to the lamps on the edge of the module or cabinet, and will not cause lamps to fall off. | It is easy to cause the lamps of the module and the box to be damaged or fall off. |

Eye-care | Long-term viewing without glare or fatigue, protecting the eyes | Long-term viewing can cause glare and fatigue, which can easily lead to visual fatigue and may cause eye diseases |

Viewing Angle | Wide viewing angles both horizontally and vertically | Viewing angle can be affected by high temperature |

Service life | The performance is almost unaffected by environmental factors and is close to the theoretical service life. | Affected by environmental factors, the service life does not meet expectations |